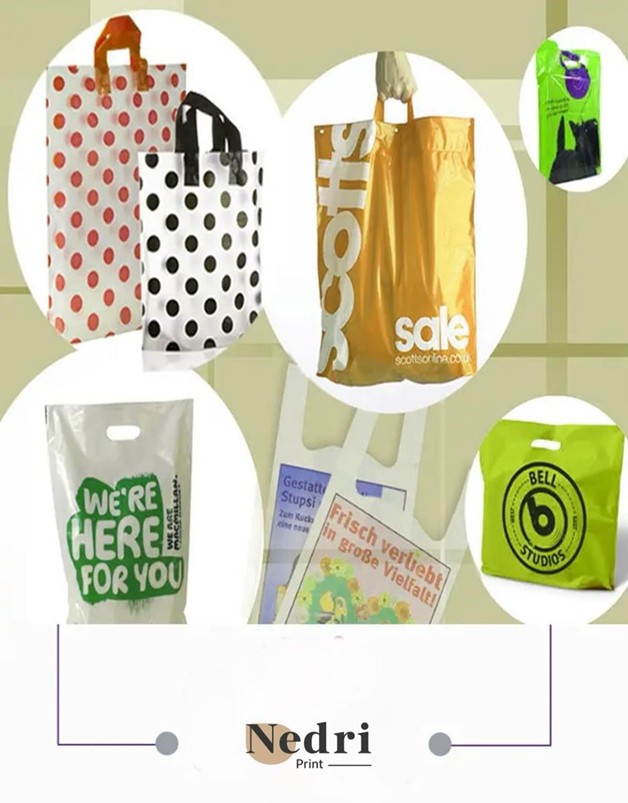

Promotional Handbag

Plastic bags, more commonly known as plastic bags with handles, are typically produced with two raw materials: nylon or nylonex.

Benefits of using a handbag

Advertising and marketing today is done in a variety of ways. One of the new and innovative marketing methods is the use of shopping bags, which are actually handbags, which can introduce many people to the brand, name, and slogan of a business.

This marketing method has led to the production of all kinds of handbags. From cloth to paper handbags, they are used as an effective way to advertise the various products of a store or brand and a large company. Imagine a handbag with a company logo or slogan printed on it can act as a moving billboard.

Handbags, while making it easier to transport and move some products and goods, are also advertising the desired product without the person using them realizing it. The production of handbags in various types and sizes and printing on handbags are done by the NedriStone Company with the best quality and at a reasonable price. Handbags that are produced in our collection.

Handbag printing

1 to 10 color flexo printing (printing various images and logos on plastic bags):

Depending on the amount of your order, the printing method is determined, which is divided into two types: 1 – flexo printing and 2 – helio printing. The printing quality is guaranteed with a guarantee that the smallest details of the image will be identified. If you do not have any design for printing, you can entrust the design of your desired image to our designers for printing.

Types of handbags

Production in various dimensions and thicknesses:

There are no restrictions on the thickness and dimensions of the production. Therefore, to place an order, you must measure the dimensions according to your packaging needs and announce them for production. As for the thickness, if you do not know what thickness you should use, we suggest that you inform us of the weight that the packaging must withstand so that we can inform you of the minimum and maximum thickness.

Lable and Packaging

Shrink nylon is a polyethylene product that is used for packaging products and is applied to the product by heat or vacuum. The many capabilities of this nylon in various industries have led most nylon manufacturers to include it in their product list.

Food Packaging

Flexible printing and packaging services are of particular importance for bread, fancy bread, cereals and flour products. In addition to protecting the quality and taste of the products, this type of packaging must also have the ability to attract customers and identify the brand.

Features of printing and packaging cakes, cookies and biscuits:

Printing and packaging cakes, cookies, and biscuits is of great importance and can have a great impact on customer attraction and maintaining product quality. Below are some of its benefits and features.

Features of printing and packaging cakes, cookies and biscuits:

Flexible printing and packaging is one of the most important aspects in the food packaging industry, especially chocolate, pastilles, and gum. Due to its special features, this type of packaging plays a significant role in attracting consumer attention and maintaining product quality.

Features of chocolate and pastel packaging envelopes and printing

Ice cream packaging is a vital aspect of the ice cream industry, helping to maintain product quality and attract consumer attention.

Ice cream packaging features:

Flexible packaging and printing for snacks and chips is a vital aspect of the food packaging industry, helping to maintain product quality and attract consumer attention.

Snack packaging features: