Anti-Fog Packaging

It refers to a type of packaging that has vapor-proof properties. This type of packaging is usually used for products and goods that need to be exposed to humidity or different temperatures and there is a possibility of vaporization or steaming. The following features and explanations can help to better understand this type of packaging:

Features of Anti-fog packaging :

Applications :

Advantages :

This type of packaging is generally an effective solution for maintaining product quality in various weather and transportation conditions.

Packaging film (CPE)

Films that are produced in the form of cast sheets using cast technology and without orientation and are produced by combining ethylene monomers are called Polyethylene Cast, abbreviated as CPE.

CPE film features

Polyethylene film, as one of the types of plastic films, has various properties that affect its performance. Some of the important technical properties of polyethylene film include:

CPP Film Production

CPP film is one of the most widely used and common types in the field of packaging. The production of CPP film requires great expertise and experience. The slightest error and mistake in the production process of CPP film causes the film to fail. The failure and loss of quality of any type of packaging, especially CPP films, causes damage, spoilage, destruction and shortens the lifespan of the products inside the packaging. With 20 years of experience in the field of packaging production, Nedri Print Company has been one of the most successful Iranian companies domestically and internationally. Currently, many Iranian and foreign companies have trusted Nedri Print

and have entrusted the design and production of their various packaging types, including CPP films, to Nedri Print.

CPP film products

Types of CPP film materials ( glossy transparent/matte transparent/metallized/milky/milky metallized ) in dimensions

18/20/25/30/35/40 (Other: from 18 microns to 250 microns)

Widths of 500 to 2300 mm are offered at Nedri Print Company.

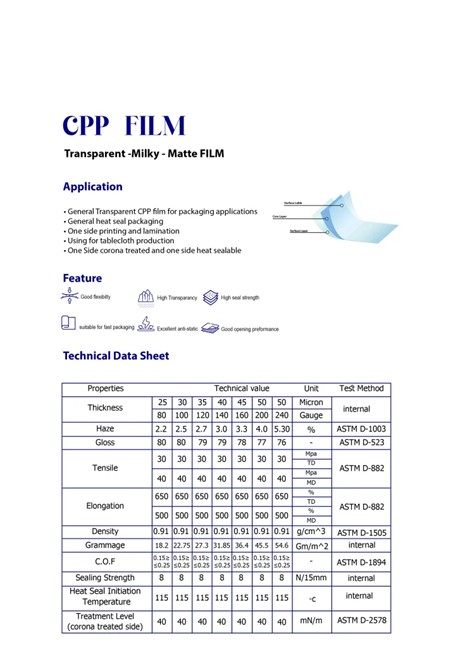

Technical specifications of CPP

What is the importance of CPP film production in product packaging?

The main concern of manufacturers after producing a product is the durability and preservation of the product. After the quality and excellence of the product, packaging is very important. It is the packaging that can fully introduce the product.

CPP film production and proper packaging can extend the shelf life of the product. If a product has the best quality but does not have proper packaging, it will definitely not be popular in the market. As a result, choosing the right packaging will preserve the characteristics and shelf life of the product.

What is CPP film?

Films produced using cast technology and a combination of propylene monomers are called Cast Polypropylene, abbreviated as CPP.

The main ingredient of CPP film is the hard, crystalline thermoplastic polypropylene, which is made from a combination of propylene monomers.

In fact, polypropylene films that are produced using cast technology without orientation and are used for envelopes and laminating with other films due to their high flexibility and elasticity

What is metallized cpp film?

If we need metallized CPP polymer , the films are transferred to the metallization machine. The aluminum wires are melted with high heat and its vapor settles on the opened layers. At this stage, the cooling chillers prevent high heat and melting of the layers.

Metallized CPP is highly resistant to moisture, water, oxygen, and sunlight, while CPP film is only resistant to moisture.

During production, attention should be paid to the product’s resistance to oxygen and, if necessary,

Production of packaging wrappers

By going through all the steps mentioned, a layer or wrapper is created. After that, depending on the type of product, it can be laminated with other layers, such as opp printed layers , to increase the thickness of the layers and wrappers.

EVA Packaging

EVA (Ethylene-Vinyl Acetate) packaging is a type of plastic material that is used in the packaging industry and other industries due to its special properties. The following is an article about the uses and properties of EVA packaging:

EVA packaging features:

Uses of EVA packaging:

Overall, EVA packaging has wide applications in various industries due to its unique properties and is a good choice for product packaging.

High-barrier polymer film

The most common challenge faced by the food industry is the preservation, care and extension of the shelf life of food products. The quality of most food products gradually decreases over a period of time, affecting characteristics such as aroma, texture, taste and color of the products. The shelf life of food products can be shortened based on the reaction of a number of intrinsic parameters such as (pH, preservatives, water activity) and extrinsic factors (temperature, humidity, gaseous environment).

One of the most important categories of polymer films is multilayer films. One of the main purposes of incorporating polymers into multilayer films is to maintain food quality and prevent the exchange of moisture and oxygen. High-barrier films are impermeable packages that, by using both polar and non-polar polymers in multilayer structures, have the ability to protect food from oxygen penetration for a long time.

Features of the film Barrier

Technical specifications (High-barrier)