Cutting Services

All cutting is done using advanced machinery that allows us to provide cut rolls with a minimum width of 50mm and a maximum width of 120mm with very high winding quality on 3 and 6 inch bobbins.

Ability to cut various types of polyethylene films – Trisbafon, etc. at high speed

Envelope Making Services

Some food manufacturers prefer to produce their own packaging in the form of pouches and market their products in them. Other manufacturers also use special and stylish pouches to make the product more visible on the store shelf, which must be presented using pouch-making machines.

For some heavy products that we cannot package with a machine, we have to use a bagged package. The production of all kinds of three-sided sewn, vacuum, four-sided sewn, cassette side, cassette bottom, easy-open zippered bags (zip-cap), sewn side bags, as well as all kinds of promotional handbags are among the products of this collection.

Heliogravure Printing

Helio or rotogravure printing is one of the intaglio printing methods. In this printing method, you can print very high quality images that closely resemble a photographic image. In this method, letters and images are engraved on the printing form and the images have interconnected light and dark shades.

Industrial heliogravure printing uses copper-coated, chrome-plated metal cylinders. Images are engraved into these metal cylinders with very small holes by a laser and then transferred to the printing form.

This printing method is only applicable to cellophane (polypropylene) packaging, which includes the types of Tresbaphone and metallized.

The NedriStone complex uses the most up-to-date and advanced heliogravure printing machine in this industry, which is one of the best printing machines in the field of printing packaging envelopes for food, health, pharmaceutical products, etc. The heliogravure printing machine is capable of printing any design and image with the finest details.

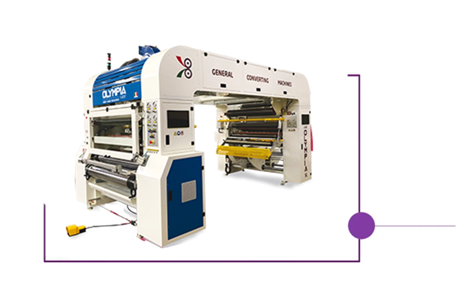

Laminate Services

One of the key benefits of roll-to-roll tapes is the ability to create a structure and process such as a laminate that exactly matches your specifications for impermeability, shelf life, protection, printing and aesthetics, as well as a feel that sets your product apart from the competition! Laminates are used in a variety of markets including pet food, frozen and deep-frozen foods, nutritional supplements, cosmetics, etc. NedriStone laminate pouches are customized to your specific product needs, providing long-term durability as well as resistance to harmful external factors. Our team can determine what type of protective layer is required and then use that to determine the required laminate materials. Our lamination technology includes two-layer and three-layer lamination equipment that uses solvent and non-solvent adhesives to improve product performance and enhance its aesthetics.

Laminated and Printed Film

PA,PE impermeable film

Film structure : PA+PE dry laminated film

Tofu, milk, tea, sausage, etc.

Food processing

The best film for thermoforming.

Product Packing Design

Are you looking for unique design and quality printing? Our team at NedriStone, with years of experience and the use of the latest software and studio facilities, is ready to assist you at every stage of the design and printing process.

Our services include:

Contact us and let us turn your ideas into reality

Flexographic Printing

Flexo printing is one of the most common printing methods for printing on non-absorbent materials. Flexo printing is a relief, rotary printing method and is printed on roll materials.

The original name of this printing is Flexography . Flexography printing is derived from the word flexus, meaning flexible. In this printing, printing is done using a flexible gelatin plate called a cliche (photopolymer plate). With flexography, uniform and uniform printing can be achieved with most polymer, aluminum, paper films for pharmaceutical, medical, food, agricultural, etc. uses with different weights. This printing has brought about many changes in the printing industry. Many flexible products and packaging are looking for flexographic printing, and this industry is progressing and growing at a rapid pace. In the Nedri Print complex, advanced 10-color flexographic printing machine technology is used .